Home › Solutions › Residential › Resin Guard™ › Resin Guard

Resin Guard™ is a smooth, protective rollcoat flooring system ideal for warehouse flooring, workshops and other commercial

flooring projects.

Resin Guard™ is a high-performance commercial flooring system specially designed to seal and protect

warehouses, workshops and other high-traffic areas.

Available in all Australian Standard colours, the completely seamless resin flooring system can be applied in all conditions, and is

resistant to wear, chemicals and impact.

Most importantly, Resin Guard™ has no strong smell and contains no solvents or flammables, so it can be installed safely in warehouses

without risk or disruption to your workers or business.

Resin Guard™ is completely solvent free. No strong smell, disruption or risk to your warehouse operations!

Resin Guard™ is formulated using only the highest quality epoxy resins and functional fillers to maximise warehouse flooring performance. No cheap solvents, diluents or fillers!

With no solvents, strong odours or flammables to contend with, and the ability to be applied in all conditions, Resin Guard™ is a great warehouse flooring choice for minimising downtime.

The glossy, chemical-resistant warehouse epoxy flooring handles spills from most commercial fluids and is easily maintained with normal cleaning equipment.

Extra chemical resistance and impact resistance options are available for the warehouse epoxy flooring system. A specialist topcoat can be

added to provide your choice of a matte or non-slip finish, as well as extra UV protection.

.jpg)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The installation of the standard Resin Guard™ system over a warehouse flooring area of 150m2 or less will take three days, with light foot traffic allowed on the fourth.

Removal of existing floors, severe surface damage or contamination, poor concrete quality, and/or larger areas will generally require more time.

Installation of the standard Resin Guard™ system typically consists of the following steps:

1. Diamond grind to remove surface contaminants.

2. Vacuum to collect dust, dirt and debris.

3. Patch small cracks and gouges.

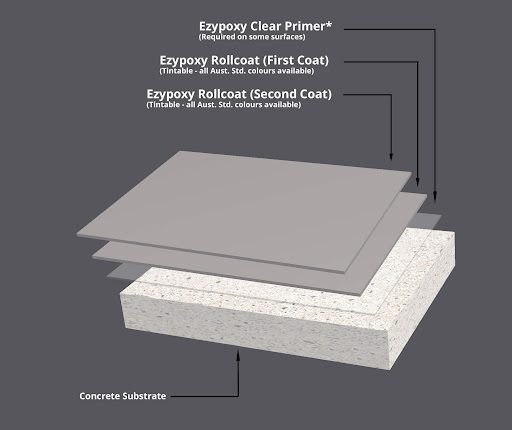

4. Apply basecoat and topcoat of warehouse epoxy flooring system - Ezypoxy Rollcoat.

5. Tidy up and hand over floor.

1. Plan to be floorless

A standard Resin Guard™ warehouse epoxy floor will take a few days and you’ll need to stay off the floor the entire time. Keep protective measures in place for the duration and don’t try to get back on it earlier than instructed.

2. Clear the floor

Remove all items from the warehouse floor - or section of warehouse floor being done - before the starting date so the installer can get straight to work. If there are heavy items that can’t be moved or other specific access issues, let them know beforehand.

3. Ensure easy access

Make sure the installer can get in and out of the work area and has access to power. If there are any restrictions in this regard, once again it’s a good idea to let them know beforehand.

4. Seal off

Footprints, bugs and dust don’t go well with freshly laid warehouse epoxy floors. Close all windows, turn off lights and block doorways. If the floor is one part of a larger project, it’s best to leave it to last to reduce the risk of other trades damaging it.

5. Make yourself available

Checking in with your installer every now and again will make sure everyone stays on the same page and the warehouse epoxy flooring project

progresses as smoothly as possible.

.jpg)