You may have come across a little confusion if you’ve ever delved into the world of epoxy concrete sealers. Have you ever noticed that some people talk about them as sealers and some talk about them as primers? Some will even interchange between the two. But is epoxy sealing and epoxy priming the same thing?

The short answer in my opinion is no. While products described as epoxy concrete sealers can be used to do both, epoxy priming serves a different purpose to epoxy sealing and being clear on this distinction can be very important when making sure you get the outcome you’re looking for.

The two questions below are based on discussions I regularly have with installers to clarify exactly what is meant by these terms and how they are used.

As I've already touched on, priming with an epoxy serves a different purpose to sealing with an epoxy, and if you’re not careful making that distinction it could come back to bite you. The key to avoiding problems is simply asking why you are priming or sealing in the first place.

In my opinion, an epoxy concrete sealer - or similar low-viscosity clear product - is used as a primer when the objective is to

increase adhesion. In other words, the product or system being applied doesn’t have sufficient adhesion or is not compatible with the

surface it’s bonding to. An everyday example would be using a clear epoxy resin to

prime before trowelling a 6:1 mix of resin and sand. At 6 parts sand to 1 part resin, there’s barely enough resin to hold the sand

together let alone provide a good adhesive layer and priming would therefore be beneficial.

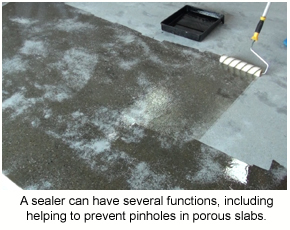

An epoxy concrete sealer used as a sealer, on the other hand, serves the purpose of closing off the substrate before you apply the

first coat of the system being installed. You can apply an epoxy concrete sealer this way for a number of reasons, including the prevention

of imperfections like pinholes, or to improve the finish of subsequent coats.

Another difference between priming and sealing with an epoxy concrete sealer is that you tend to only require a single primer coat whereas

you can often require multiple sealer coats. For example, you apply an epoxy concrete sealer to seal a porous surface and notice it

looks sealed/glossy in some areas, but bone dry in others. If I was concerned about defects, I’d want to apply another coat and see a

consistently sealed subfloor before pushing ahead with the intended flooring system.

A big question that comes into play on this topic is whether you always need to prime or seal with an epoxy concrete sealer. Once again, the

answer is no.

You can buy primerless products that are resin rich enough and surface tolerant enough to be applied directly onto the substrate, eliminating the extra labour and product required to apply an epoxy concrete sealer as a primer. You can also get surfaces that aren’t weak or porous and won’t need an epoxy concrete sealer to make sure they're suitable for coating.

Finally, is it worth priming and/or sealing “just in case” to guarantee better results? You guessed it - no, not always. In fact, I'll give you an example in the second question below where using an epoxy concrete sealer actually caused trouble.

I know many epoxy flooring installers that use an epoxy concrete sealer on every job, but does it always guarantee better results?

As discussed in the first question, I actually consider epoxy priming and sealing as different based on the roles they perform. Regardless

of what they’re called or how they’re used, a big question that comes into play on this topic is whether you always need to prime or seal.

For me, the answer is no.

You can buy products that stick well directly to the substrate, eliminating the need for what I call "priming". You can also get

well-laid slabs that aren’t porous or powdery and won’t need what I call "sealing" to hold the surface together or prevent

bubbles.

To take the argument against priming or sealing EVERY time a little further, I can even give you examples where it actually caused trouble

rather than solved it. In one particular case I remember, the use of an epoxy concrete sealer only managed to compromise the adhesion

and cause some massive headaches for the installer. There’s actually a lot to learn from this story and it’s worth covering in detail, so

I’ll break it down for you here.

The installer at the heart of it all wanted to make sealing a standard step in all of his garage flake jobs so he could overcome the

variation in concrete quality he was seeing and simplify the quoting process.

The solution he came up with was to apply a certain water-based epoxy concrete sealer as a sealer on all the slabs. Being a very cheap

product, the overall increase in material cost was minimal and far less than other sealing options - a big bonus in his view. The product

manufacturer also recommended adding extra water to make it easier to apply and allow it to soak into the slab more. Fantastic! Even less

cost.

Intercoat adhesion tests were conducted to prove the concept and the water-based epoxy failed concrete every time. It was fast enough and seemed to seal the surface well enough, so his plan all seemed to be falling in place.

Just when he thought he had it all worked out, a few problems began to appear. On one floor a small piece of coating let go directly beneath a rear wheel. Hot tyre pick-up, as it’s known, is a pretty common occurrence on garage floors covered with cheaper floor paint. The heat of the rubber softens these films, creating a temporary bond strong enough to prise small sections off the concrete. For two-pack epoxies, however, the heat isn’t an issue and this kind of failure can normally be traced back to surface preparation instead. When the underside of the failed coating was examined, there was a full layer of concrete visible suggesting that wasn’t the problem either. Something else was going on.

At the time it was determined to be particularly weak concrete at fault, probably due to it being rain affected or something like that. Anyway, the area was patched and life moved on.

More time passed, and another failure popped up...same problem, different floor. Initially the same conclusion was reached, but maybe there was more to it? One failure wasn't enough to be concerned about and two in the space of a short time could’ve just been a coincidence, however some digging was done anyway to see if a pattern was emerging.

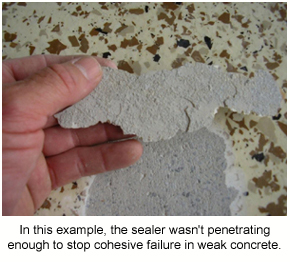

We understood the system worked fine on sound concrete via the adhesion tests, but when a weak slab was subject to stress (hot tyres in this

case), the concrete would let go. We suspected the water-based epoxy concrete sealer was doing its job of sealing the slab to make it less

porous, but was it somehow compromising the adhesion?

Further analysis revealed some very interesting facts. The WBE was a high-solids product, but when diluted as per the instructions it would

end up at around 45%. Based on the coverage the contractor was getting, it meant a build of 37 microns was being achieved at best, which

isn’t much of a sealer at all!

In fact, very little resin was penetrating into the slab to provide the reinforcement these weak slabs needed. Because not enough was being

used, it was simply sitting on the surface and forming a very flimsy basecoat of sorts that offered no extra cohesive strength to the

concrete at all. Ok for good slabs, but disastrous for weak slabs.

The only solutions to this problem weren’t exactly what the installer wanted to hear:

The moral of this story is you must ensure the epoxy concrete sealer you are using is suitable for the intended purpose of either

priming or sealing, otherwise you could end up making the problem worse. Just putting an epoxy concrete sealer down in any old fashion

definitely doesn’t guarantee better outcomes.

What is your experience with epoxy concrete sealers for priming and sealing? Have you ever been in the situation where they were causing

problems rather than solving them?

|

|

| Ezypoxy Clear Epoxy Sealer | Jaxxon 1335 Clear Epoxy Binder and Sealer |

Real World Epoxies has formulated, manufactured and supplied high-quality epoxy concrete sealers and primers for more than two decades. We stand behind our products because we only use proven, high-quality materials that we know will perform as expected. You can trust our clear epoxy sealers for your epoxy flooring project.

Let us help you with your concrete sealer needs when you fill out one of our contact forms or call us on 1300 EPOXIES (1300 376 943).

To help build a strong resin flooring industry that sits alongside timber, carpet, tiles and vinyl as a mainstream flooring option.

To eliminate preventable failures

that hurt the resin flooring industry

and prevent it from reaching its full potential.