Home › Advice › Know How › Knowhow

11 Common Decorative Flooring Problems

I commented in another post that while decorative flooring can be a thrilling field to work in, it’s actually quite demanding and holds many traps contractors need to be aware of.

In that particular post (Decorative epoxy

flooring - 5 tips to make sure contractors get paid)

I focussed more on the topics of client and project management; this time I want to get into the nitty gritty a little more and take a look

at some application issues that provide regular headaches in the application of one particular type of decorative flooring - metallic

epoxy flooring.

I was actually reminded just how common and damaging these defects are on a recent project when all eleven on the list I’ve compiled appeared on the one floor. That’s right, all of them! While that story is a bit of a nightmare, the good news is that all of these are very much avoidable and I’ll explain how right now.

While the list I’ve put together is a long and potentially off-putting one for some epoxy users, the bright side is that all of these

problems are very preventable. By being aware of the key risk factors and adopting a few good habits, you’ll be able to do some

great-looking decorative floors and enjoy what I find is a very exciting field of epoxies.

Soft spots

I’ve already covered soft spots thoroughly in a previous

post, however for the sake of this discussion there’s one aspect I want to highlight again.

The number one source of soft spots is poorly mixed product from the sides and bottoms of buckets, and it can so easily be avoided by scraping during the mixing process. If you’re going to do decorative flooring, or epoxy flooring of any kind really, you simply must have a good set of scrapers to help you mix properly - long enough to reach the bottom of mix buckets and at least one with a flat edge.

Crawled areas and fisheyes

Crawling in decorative flooring is almost always a response to contamination, so the clear aim when talking prevention is to remove all

sources and work with clean, dry surfaces at all times. When thinking about potential sources of contamination, most people know about

oil, grease and silicon on the concrete itself, however not everyone thinks about other threats such as airborne dust, residue on tools,

or even handwash sprays.

A couple of other tips when it comes to crawling: contamination can seep through coats, so don’t assume a second coat won’t crawl, and, it may sound obvious, but don’t let anyone walk around on the floor in bare feet between coats! Oils from the skin can be enough to create troubles in the next coat.

Bugs

Unless the decorative flooring products you use have some sort of insect repellent or toxin in them, there’s not much you can do about a few

flies or moths landing in a wet film. It’s going to happen at some point. There’s a big difference, however, between dealing with a fly

here or there and a full plague. To stop the latter from ruining a decorative floor, you’ve got to be really careful sealing rooms off and

doing some good common sense stuff, such as not leaving lights on overnight.

Debris

The surface preparation process leaves a lot of dust and debris on the floor, and you’ve got to make sure it’s all collected before you get

going with application on decorative floors. If you don’t, then you can have all sorts of lumps and bumps that stick out like a sore thumb

and can lead to other problems as well. Investing in a quality vacuum system and meticulously inspecting the floor before you start

splashing resin around are the best ways of avoiding such headaches.

You should also be very wary of trudging in gunk from your mix area and applying in hard-to-reach areas, especially when cutting in.

You can have a spotless concrete slab without a speck of dust on it and bring all your hard work undone by dragging out hidden dirt

from underneath a skirting board.

Comets

One of the problems debris can lead to is the appearance of streaks or “comets” on a metallic decorative floor. These occur when the

metallic pigment gets caught and has to flow around a protrusion of some kind. Now, on some designs I personally think comets can add

something to the look rather than be a fatal flaw, however not every client thinks the same way and even more so if they weren’t

expecting it. To make sure you don’t get unwanted comets appearing in your metallic decorative floors, once again you’ve got to remove all

loose debris and scrape off or sand flat anything sticking out on a dried film. Comets can also be caused by lumps of metallic pigment

or filler in a clear epoxy resin, so make sure you mix well!

.jpg)

Metallic sinkholes and drips

These areas look like concentrated spheres or rings of metallic pigment and generally show up as small imperfections that can, like comets,

be interpreted as defects by the client.

Sinkholes, as I call them, are formed by the resin flowing into pinholes that haven’t been patched - the resin flows down into the throat while the bulkier pigment particles gather at the top. The prevention all comes down to blocking the pinholes first, which is typically done by scratching in a patching compound before the metallic coat goes down. Drips of resin off a trowel can cause a similar, perhaps more blob-like effect, which can also be viewed unfavourably if they’re bunched in one part of the floor.

Visible joints

Filling joints to create a completely seamless decorative flooring finish is a popular choice for floor owners and finding a way to do

it well will save contractors plenty of headaches.

The biggest threat with these is failing to level them completely, which is usually a result of the patching compound slumping and making the joint visible in subsequent coats. Some types of decorative epoxy flooring, such as flake epoxy floors, are more forgiving with this type of imperfection, however with metallic epoxy flooring there’s nowhere to hide as the pigments tend to settle in the shallow channel and create a vivid “ghosting” effect.

To avoid joints showing through in a decorative floor, the obvious goal is to make sure the patch is flat and stays flat. If the

material you use is prone to slumping, this may mean you’ll have to patch more than once, or over-fill the joint and grind flat before

the first coat goes down.

Holidays

Many decorative floors are applied at 1mm/40 mils or over, which makes you think holidays - areas with no or very little resin - would be

easy to avoid. Unfortunately it can and does happen. The logical danger zones are along the edges of the floor, around protrusions and

in other hard-to-reach spots.

With these types of imperfections, there’s really nothing to say apart from the fact you have to slow down and be careful. The best tip I can give is to cut in on all your floors. Many skip this step for the sake of a little extra speed and end up with bare spots that are very tricky to fix. You’re much better off mixing up a smaller quantity of resin first, using a smaller tool and taking your time to get these areas right.

Also, keep film thickness and application techniques consistent with the rest of the floor otherwise you risk creating a different pattern that stands out for the wrong reasons.

Humps, valleys and concrete flatness

You can get an idea of how flat a slab is by lying a straight edge tool down and seeing if there are any gaps between it and the concrete

underneath. In my experience, not many contractors do this before quoting a job, and they’re taking a massive risk because the flatness will

have a big impact on the end result.

Unlike coloured rollcoats that hug the contours of the slab, a decorative clear epoxy will flow freely and that can create havoc in all sorts of ways - high points allow the colour beneath to show through more and can look patchy, while low points can look flooded/messy. To top it off, the typically high gloss levels on decorative floors has a knack of showing owners how uneven their floor actually is (which is often mistaken for contractor or product error).

You’d be surprised how many slabs don’t meet official flatness standards, so I’d strongly advise you get into the habit of testing every

slab you work on. If it is up and down, explain to the client why it needs to be levelled first and put it in the quote.

.jpg)

Loose fibres

I’ve raised this point plenty of times in other epoxy flooring articles like "The forgotten gear causing epoxy contractors

trouble", so I won’t say much more here except that it's common sense on beautiful, glossy decorative floors that you want to

minimise the chances of anything getting stuck in the film and appearing as a defect. Stray fibres from roller covers are a constant

source of hair-pulling frustration in this sense, so if you’re rolling at any point you’ve got to find ones that are as close

to lint-free as possible. Covers with a woven weave and phenolic core I believe are your best bet in this regard.

Resin where it shouldn’t be

The odd splash of resin on a skirting board is probably what first comes to mind here, however I want to focus instead on a less

familiar example of resin ending up where it shouldn’t. Specifically, I’m talking about the overflow that can happen on taped boundaries

at entrances, exits and transitions.

As I’ve alluded to a number of times already, metallic decorative floors can flow a lot more than other systems and this can be disastrous if it involves crossing a tape line. The easy solution here is to simply hang around for 30 minutes or so after application so that you can respond to any undesirable resin migration. A lot of contractors hurriedly clean up and head off to the next job or go home, but if you stay that little bit longer and watch what the resin is doing you can stop this kind of thing before it turns into a big rectification drama.

So there you have it: eleven very common defects that cause major decorative flooring hassles, yet thankfully come with some pretty simple

preventative measures. Overall, the underlying message is that decorative flooring is not a one-size-fits-all, get-in-get-out operation.

It’s a highly customised flooring service and to do it well you need to slow down and pay attention to the details - prepare thoroughly,

assess the floor beforehand, understand the client and their needs, apply carefully, observe and respond to what the resin is doing,

and, ultimately, leave behind a stunning decorative floor.

Got a decorative flooring project you'd like to talk to us about?

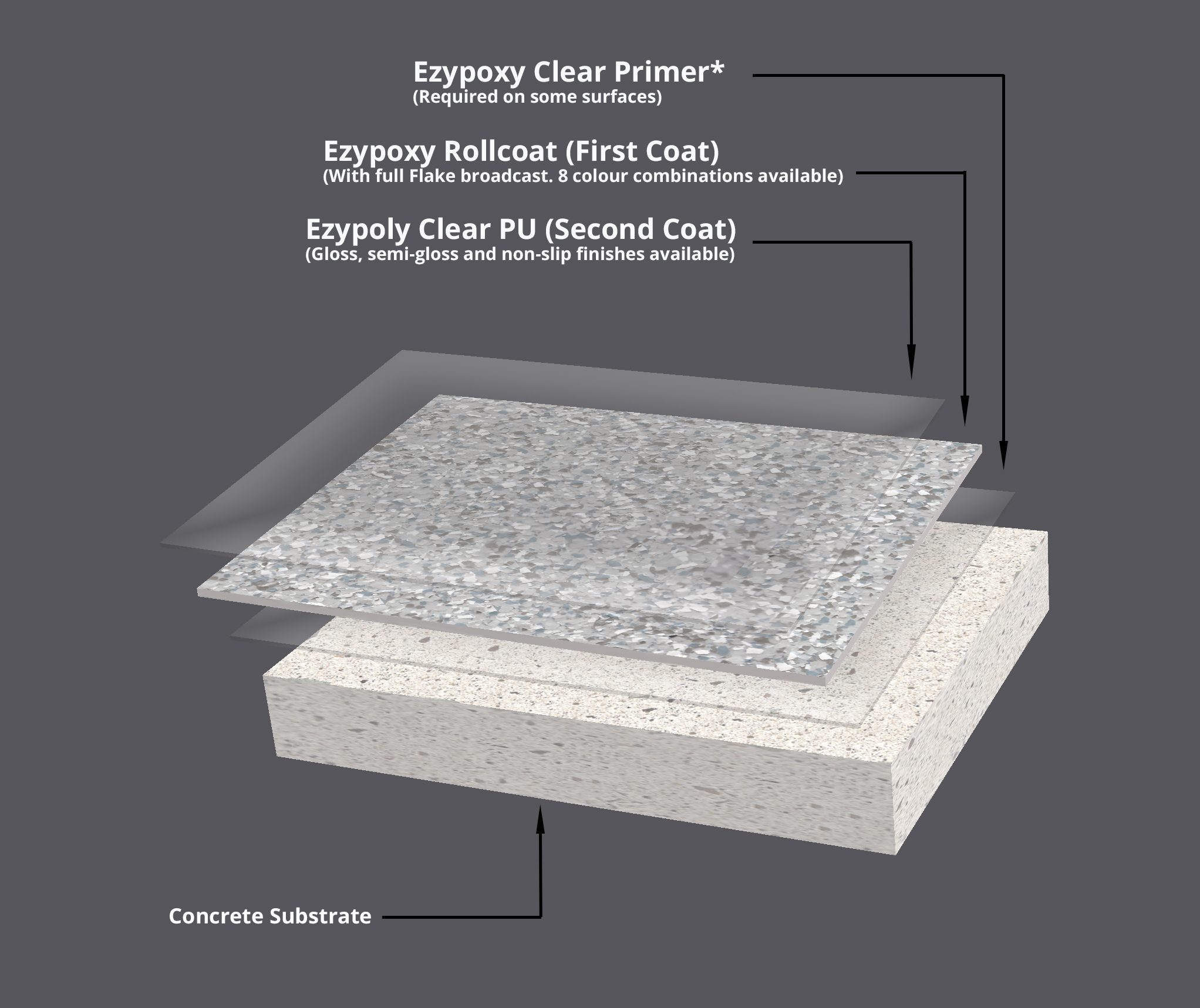

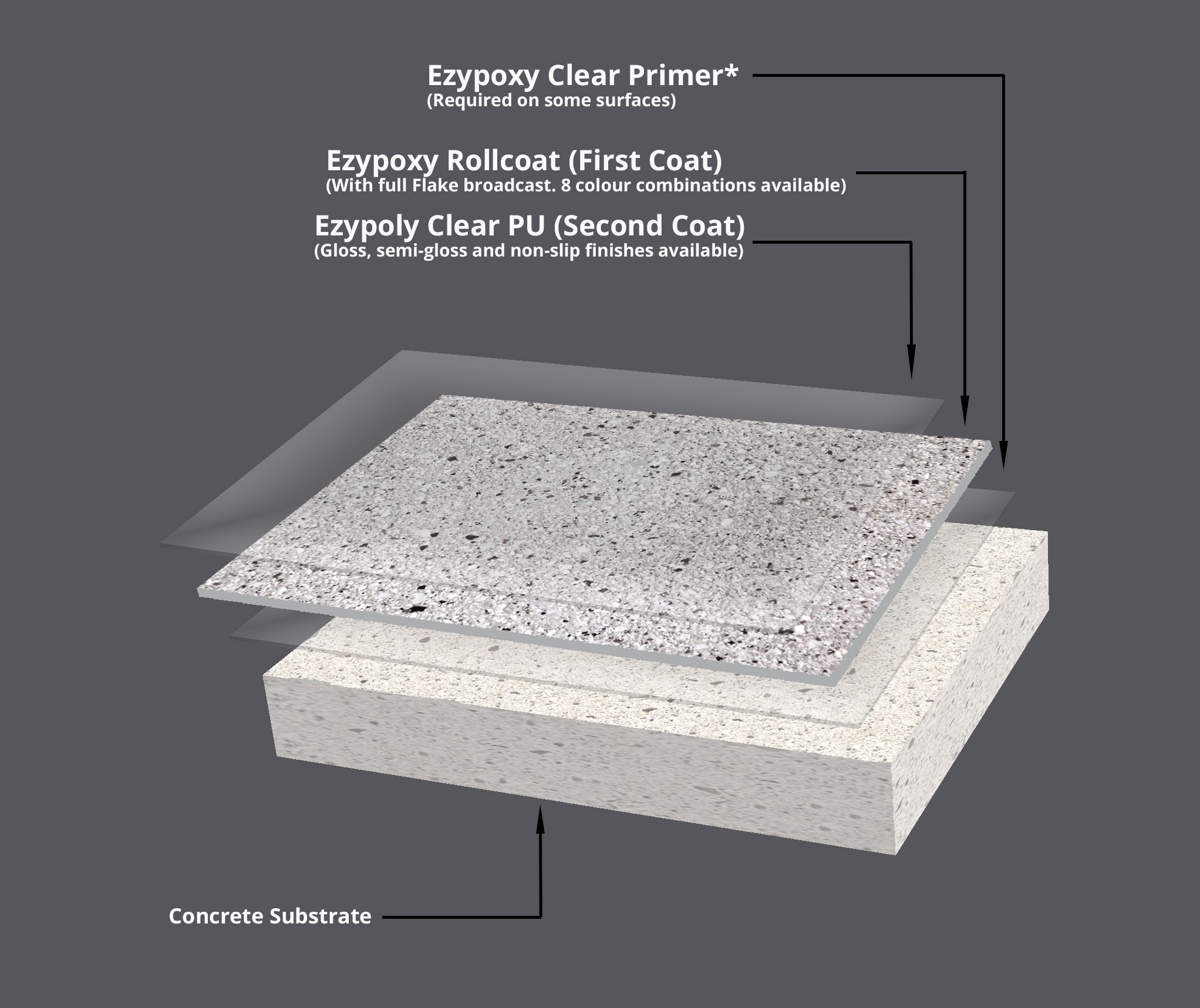

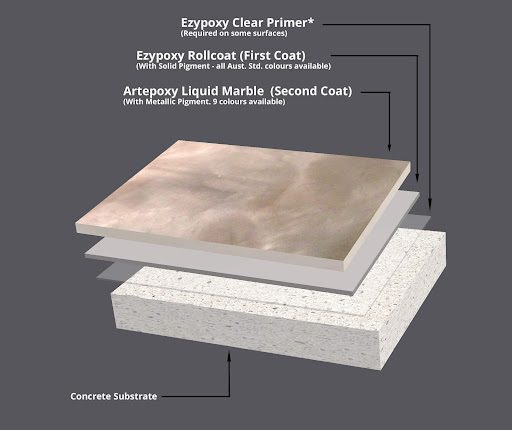

Our decorative flooring systems

Read more about our decorative flooring systems on the individual system pages:

|

|

|

|

|

Resin Vinyl (6mm Flake) Epoxy Flake Flooring System |

Resin Granite (Stone Look) Epoxy Flake Flooring System |

Resin Marble Metallic Epoxy Flooring System |

Resin Rustic Decorative Epoxy Flooring System |

Want more information on decorative flooring?

You can find more decorative flooring information on our site through the following links:

Want to see examples of decorative flooring projects?

If you're looking for inspiration with your decorative flooring project, you can view a selection of our past projects here:

Decorative flooring gallery

.jpg)

.jpeg)

.jpeg)

.jpg)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpeg)

.jpeg)

-

Products - Use genuine decorative epoxy resins and metallic pigments that are designed specifically for these types of

projects:

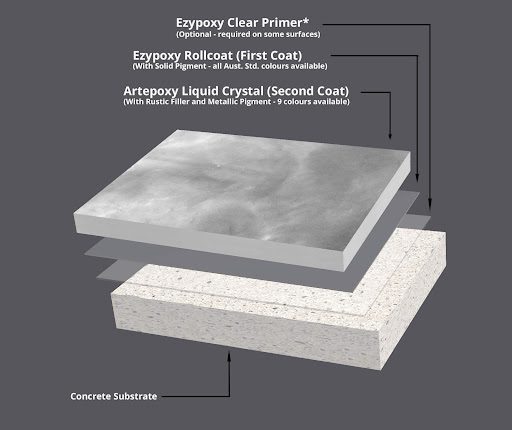

- Artepoxy Liquid Crystal - Clear Decorative Epoxy Resin

- Artepoxy Liquid Marble - Metallic Epoxy Floor Coating

-

Systems - Specify specialist decorative systems with proven performance:

- Resin Vinyl - Epoxy Flake Flooring System

- Resin Granite - Epoxy Flake Flooring System

- Resin Marble - Metallic Epoxy Flooring System

- Resin Rustic - Decorative Epoxy Flooring System

-

Learning - Learn more about decorative flooring, and much more, with our online courses:

- Epoxy Flooring How To Videos

- Epoxy Flooring Short Courses

- Bronze Card Course

- Silver Card Course

-

Ask a question - If you have any questions you'd like to ask us about this topic, hit the support button below:

_800x271a.png)